Labeling medical devices

Medical device labeling is complex and highly regulated. For example, the FDA governs the Unique Device Identification system (UDI) in the US, while the European Union governs Medical Device Regulations (MDR).

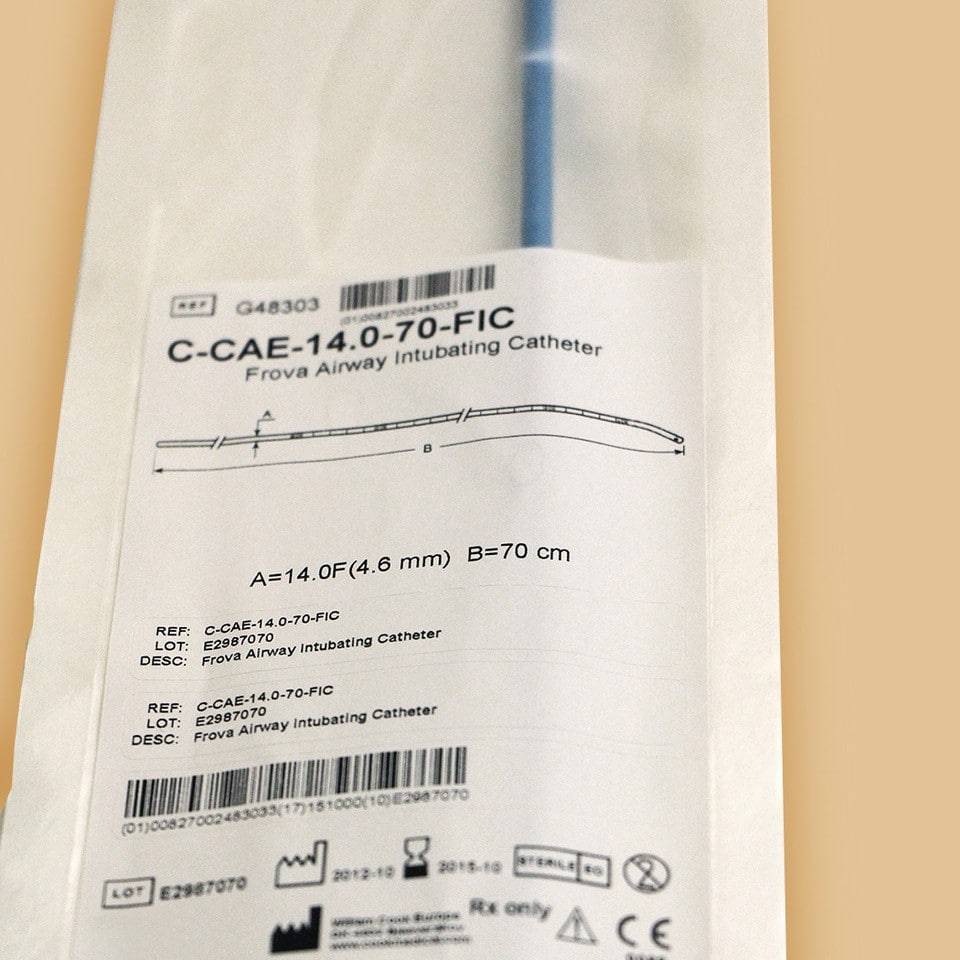

These systems standardize and identify medical devices through distribution and use through their intended lifecycle. Thermal transfer is used for individual device labeling and packaging such as unit packs, inner packs, and master cartons. Label reliability is vital for supply chain efficiency and patient safety.

In the USA, the UDI (Unique Device Identification) system requires a unique traceability code, a barcode, and a representation of the product on the label for every medical device. Thermal Transfer enables durable, long-lasting barcode label printing plus logos, product drawings, and other minor characters — providing critical flexibility for medical device manufacturers. Medical device manufacturers wishing to sell their products in the USA must submit a Drug Master File to the FDA to validate the safety of all of the product’s components, including printing inks. ARMOR-IIMAK supports users in this area by making ink composition information available to the FDA.

Hospitals and clinical establishments have the same need of identification and traceability to assure that their patients receive the safest stay.

Why using thermal transfer technology for this application ?

Ensure regulatory compliance and patient safety in Medical Device labeling with thermal transfer printing designed to withstand repeated handling, temperature extremes, and chemicals while maintaining legibility.

For this application, we recommend the following products: