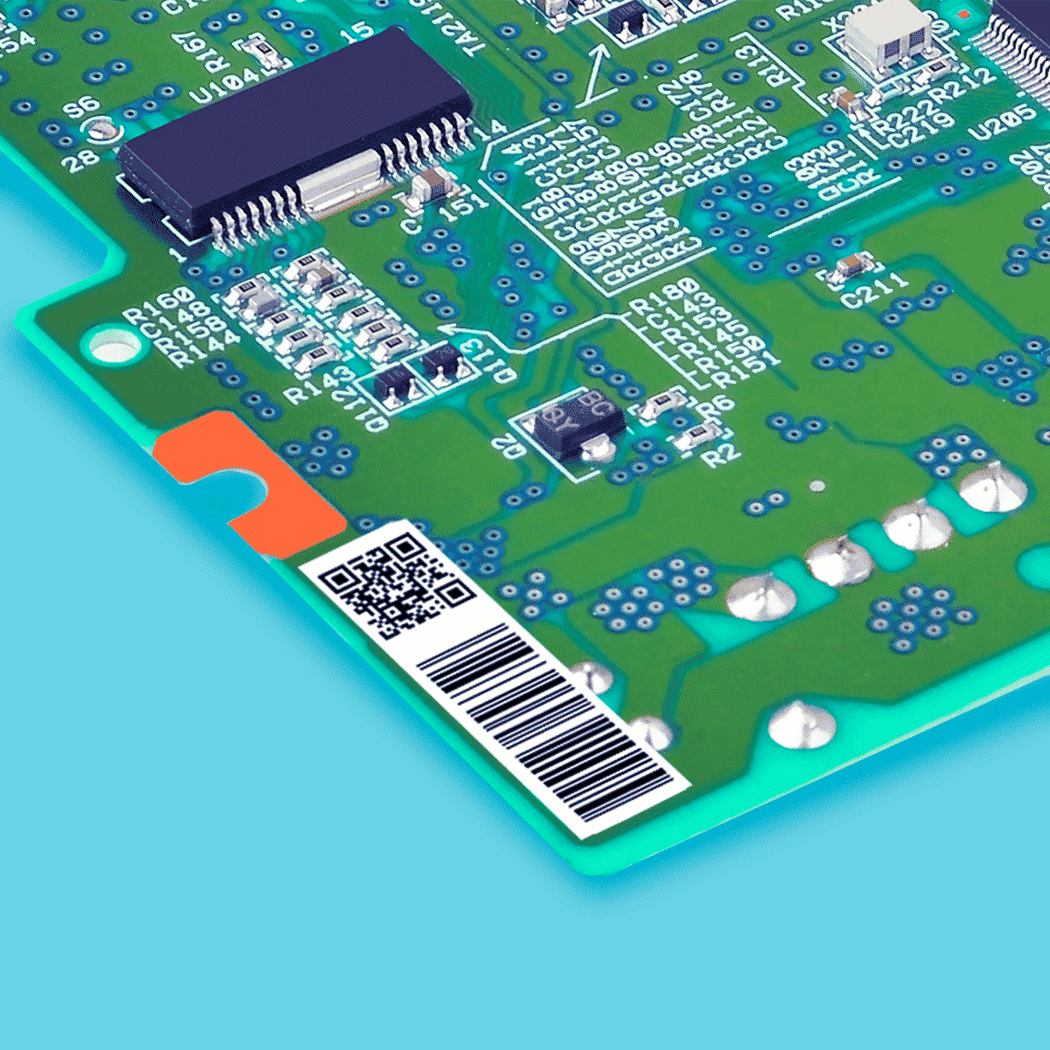

Labeling printed circuit boards

To ensure long-term PCB traceability, most boards are barcoded to communicate information such as:

- Board manufacture date

- Component lot numbers

- Test data

However, poor quality or damaged printing can impact production process monitoring, logistics, and the use of the printed circuit board (PCB) in the end product.

Such message legibility and durability requirements are at the heart of selecting a print solution.

Many individual PCB components, including capacitors, resistors, and transistors, are also marked or labeled with similar information. Labels and markings need to be scannable at a tiny size and resist the high temperatures and harsh chemicals associated with hot soldering, aggressive fluxes, and acidic cleaners.

Regulation

Within the range of inkanto Thermal Transfer ribbons there are solutions for complying with EU Directives 2011/65/EC (RoHS) and 2002/96/EC (WEEE), as well as meeting the restrictions of halogen compounds and the UL standard on printed label durability.

Why using thermal transfer technology for this application ?

Thermal transfer printing technology for printed circuit board

Thermal Transfer technology is the most reliable print technology for printing unitary information on pcb labels.

The high definition of the print head produces extremely accurate printing of all types of barcodes (vertical, horizontal, datamatrix, 2D, etc), alphanumerical characters and logos, even on very small labels.

ARMOR-IIMAK Resin inks (AXR® family) in combination with synthetic labels (polyester, polyamide, polypropylene or polyimide) offer the best solution in terms of print quality and resistance to temperature, abrasion and solvents.

For this application, we recommend the following products: