ARMOR-IIMAK worldwide

-

Local dedicated teams since 1989

-

Local stock for fast order fulfillment

-

Headquarters located in Nantes, France

-

Bringing daily sales and customer support to partners

ARMOR-IIMAK in your region

-

Local dedicated teams since 1989

-

Local stock for high reactivity

-

Office located in Letchworth Herts, England

-

Bringing daily sales and customer support to partners in the UK, Ireland, Denmark, Norway, Sweden, and Finland.

ARMOR-IIMAK in your region

-

Local dedicated teams since 1989

-

Local stock for high reactivity

-

Office located in Letchworth Herts, England

-

Bringing daily sales and customer support to partners in the UK, Ireland, Denmark, Norway, Sweden, and Finland.

ARMOR-IIMAK in your region

-

Local presence since 1922

-

Offices, the production site, and local stock located near Nantes, France

-

Bringing daily sales and customer support to partners in Europe, Northern Africa, and the Middle East.

ARMOR-IIMAK in your region

-

Local dedicated teams since 2014

-

Local stock for fast order fulfillment

-

Offices located near Bangalore and New Delhi

-

Bringing daily sales and customer support to partners

ARMOR-IIMAK in your region

-

Local dedicated teams since 1999

-

Local stock for fast order fulfillment

-

Offices located near Singapore

-

Bringing daily sales and customer support to partners in Singapore

ARMOR-IIMAK in your region

-

Local dedicated teams since 2014

-

Local stock for fast order fulfillment

-

Offices located near Johannesburg and Cape Town, South Africa

-

Bringing daily sales and customer support to partners in the south region of Africa

ARMOR-IIMAK in your region

-

Local dedicated teams since 2017

-

Local stock for fast order fulfillment

-

Offices located near Mississauga

-

Bringing daily sales and customer support to partners in Canada

ARMOR-IIMAK in your region

-

Local presence since 2004

-

Offices, the production site, and local stock located near Xiaolan (Zhongshan), Zhuhai, and Shanghai

-

Bringing daily sales and customer support to partners in China, Taiwan, and Hong Kong.

ARMOR-IIMAK in your region

-

Local dedicated teams since 2006

-

Office located in Seoul

-

Bringing daily sales and customer support to partners in all parts of Korea.

ARMOR-IIMAK in your region

-

Local dedicated teams since 2000

-

Office located in Tokyo

-

Bringing daily sales and customer support to partners in all parts of Japan.

ARMOR-IIMAK in your region

-

Local presence since 1983

-

Offices, production sites, and local stocks near Cincinnati, OH, and Buffalo, NY

-

Bringing daily sales and customer support to partners in the USA and some countries in Central and Latin America.

- 350 000Daily ribbon slitting capacity to support our customers’ development

- 1000Number of meters of film coated each minute on our most newest production line

- 130People dedicated to daily customer care

- 1500Number of employees dedicated to Thermal Transfer technology

1922

Creation of GALLAND & BROCHARD company in Nantes, France

ARMOR

1925

Creation of the ARMOR brand

ARMOR

1964

ARMOR is the first company to produce carbon films in France

ARMOR

1970s

First TV commercial

ARMOR

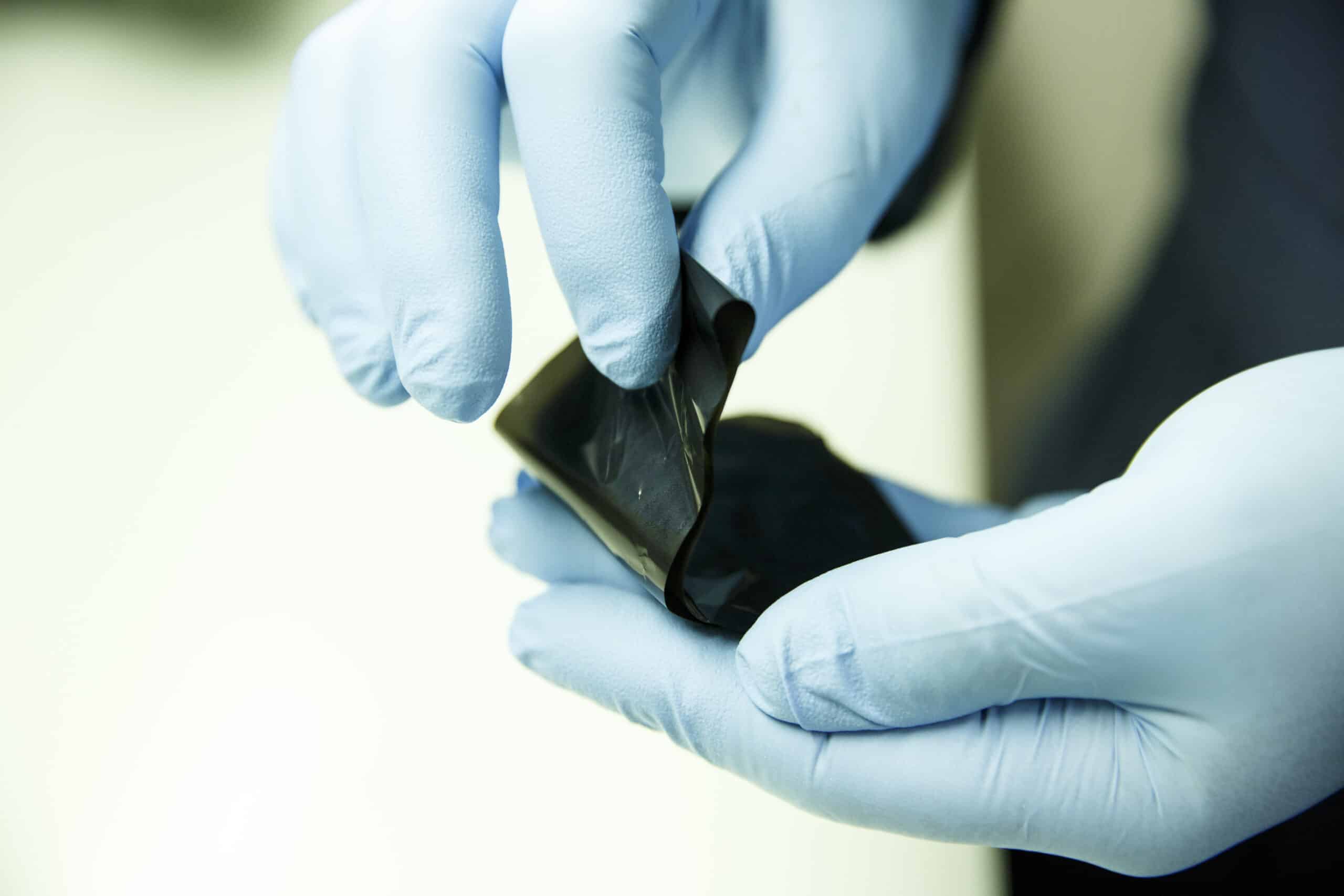

1980s

Pioneers of Thermal Transfer technology

ARMOR

1st company to produce Thermal Transfer ribbons in Europe

IIMAK

Creation of the International Imaging Materials, Inc. (IIMAK) to produce Thermal Transfer ribbons in North America. The first thermal transfer ribbon in North America was produced in Amherst, NY.

1990s

Growth of 2 leaders

ARMOR

Opening of the first building of the new facility dedicated to Thermal Transfer ribbons.

IIMAK

Construction of a 300,000 square feet manufacturing plant with expanded research and development.

Innovative online presence with a password-protected site for customers.

2000s

Regional expansion

ARMOR

Opening of 4 slitting subsidiaries outside Europe: USA, Singapore, China, and Brazil.

Launch of an ambitious sustainable development program. First breakthrough with SolFree®, the 100% solvent-free production process reducing the CO2 emissions of each ribbon.

IIMAK

2 slitting entities opened in Brazil and Europe (Belgium).

Launch of Clean Start® printhead cleaner on all thermal transfer ribbons.

2010s

Investments and innovation

ARMOR

The creation of 9 new slitting subsidiaries on all continents: Canada, India, South Africa, East Africa, Mexico, Colombia, and Turkey.

Launch of inkanto, the brand applied to ARMOR ribbons, which come with innovative add-ons such as a lifetime guarantee or certificate of conformity.

Massive investments in quality and high-performance production equipment. Including automated slitting robots and high-performance coating machines running up to 1000m per minute.

IIMAK

Acquisition of converting partner in Mexico to develop a stronger market position in Central America.

2021

A new era for a brighter future

ARMOR acquires IIMAK to offer the best in Thermal Transfer.

ARMOR-IIMAK is born.

Sustainable development

ARMOR-IIMAK takes responsibility for and has set clear guidelines to reduce the environmental impact of its industrial activities. Since we embarked on a true sustainable strategy in 2008, ARMOR-IIMAK is now offering more sustainable products and services. Environmentally-conscious ribbon design, waste management, manufacturing processes and regulatory data: have a look to the sustainable solutions ARMOR-IIMAK is offering.

ARMOR-IIMAK social innovation

Social responsibility is the result of a collective and constantly evolving process. Through its activities, the group strives to stimulate the drivers of sustainable growth based on innovation and ethics. The group has identified 6 main objectives relating to the impact of its business activities.

-

Governance and ethics

-

Employee development

-

Circular economy

-

Renewable energy

-

Responsible traceability

-

Local solidarity

Long term partnership

ARMOR-IIMAK produced its first Thermal Transfer ribbons in 1983 and grew to become the worldwide leader with a local presence in all regions of the world. You experience our product solutions in your life every day from barcodes and clothing tags to food expiration dates and warning labels.

We place our focus on relationships, assuring that our thermal transfer product solutions align with your needs as our industry grows. With over 1700 employees worldwide, we’re able to support you from near and far and our team is committed to providing reliable traceability solutions that will guarantee mutual growth.

- 350 000Daily ribbon slitting capacity to support our customers’ development

- 1000Number of meters of film coated each minute on our most newest production line

- 130People dedicated to daily customer care

- 1500Number of employees dedicated to Thermal Transfer technology